In the world of modern manufacturing and engineering, height gauges and calipers are two of the most widely used precision measuring tools. Whether you’re setting up a CNC machine, inspecting a machined component, or checking part tolerances on the shop floor, these instruments deliver the accuracy and repeatability every technician depends on.

Understanding Height Gauges

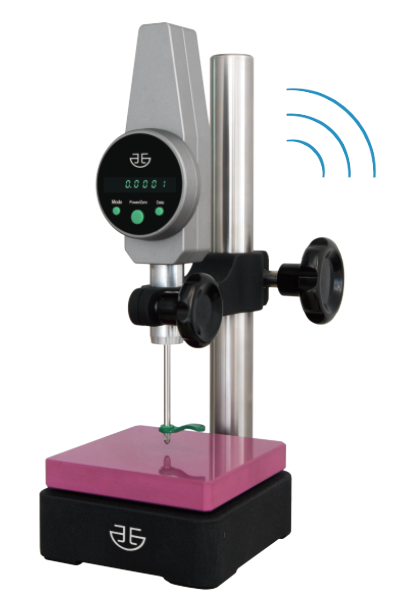

A height gauge is an indispensable measuring instrument used to determine the height of objects or mark vertical distances on workpieces. Commonly found in machine shops and inspection departments, the height gauge ensures precise layout work, dimensional checks, and tool alignment.

There are three main types of height gauges:

-

Vernier Height Gauge: The traditional version using a vernier scale for manual readings.

-

Dial Height Gauge: Provides easier readability through a dial indicator.

-

Digital Height Gauge: Offers electronic readouts with data output, allowing for faster, error-free measurements.

A digital height gauge is ideal for high-precision manufacturing, often providing resolutions up to 0.001 mm. It’s frequently used in CMM (Coordinate Measuring Machine) setups or surface plates for accurate reference height measurements.

The Role of Calipers in Precision Measurement

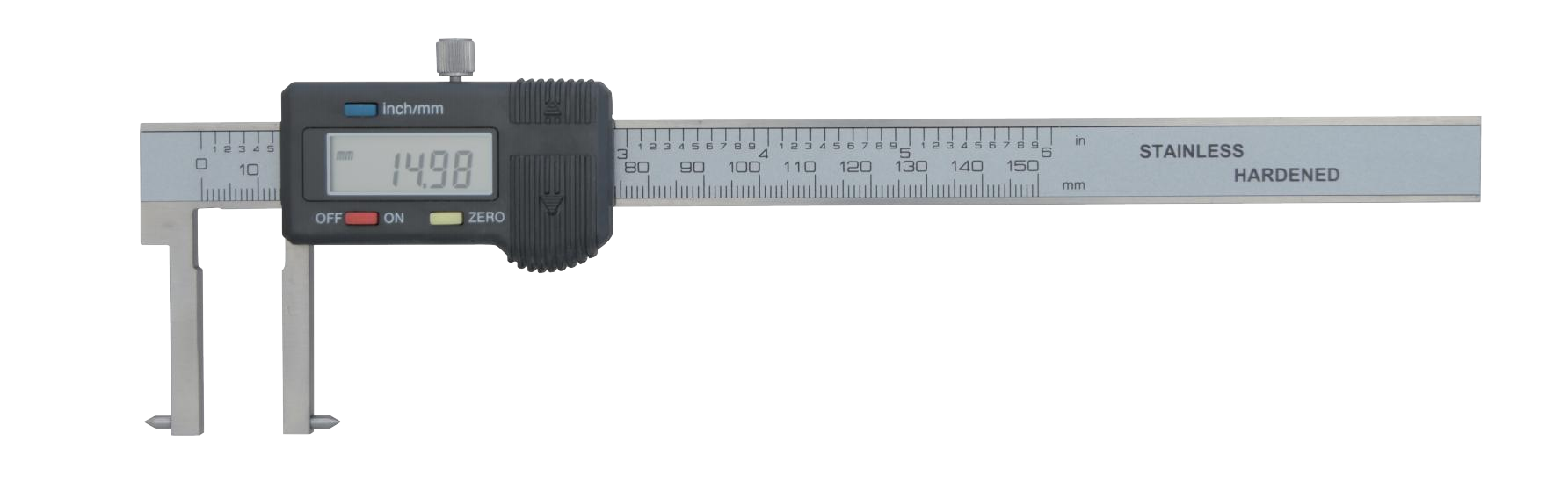

While height gauges handle vertical measurements, calipers are the all-rounders of dimensional inspection. A vernier caliper, dial caliper, or digital caliper can measure inside, outside, and depth dimensions with great precision, making it a versatile tool in any workshop or laboratory.

A digital caliper provides a quick and reliable way to measure parts, often used in assembly, fabrication, and machining processes. It allows users to easily switch between metric and imperial units, store data, and connect to computers or SPC systems for quality documentation.

Key Benefits of Using Height Gauges and Calipers

-

High Accuracy: Both tools can achieve micron-level accuracy, critical for precision manufacturing.

-

Ease of Use: Modern digital versions reduce human error and provide clear readings.

-

Versatility: Suitable for a wide range of materials — from metals to plastics and composites.

-

Durability: Quality instruments from brands like Meapert are built with hardened stainless steel and advanced electronics for long-term reliability.

Applications Across Industries

-

Machining & Toolmaking: Setting tool offsets and verifying workpiece dimensions.

-

Automotive Manufacturing: Measuring component thickness and alignment tolerances.

-

Aerospace & Defense: Ensuring part conformity to strict dimensional standards.

-

Quality Control Labs: Performing precise inspections on surface plates.

Why Choose Meapert Measuring Tools

At Meapert, we design and manufacture precision measuring instruments that deliver consistency and accuracy across demanding industrial applications. Our digital height gauges and vernier calipers combine ergonomic design, advanced materials, and certified calibration — ensuring that your measurements remain precise every time.

Conclusion

Both height gauges and calipers are indispensable in achieving top-tier precision. Whether you’re calibrating tools, inspecting parts, or verifying production runs, investing in reliable, well-calibrated instruments ensures long-term efficiency and accuracy.

Explore Meapert’s full range of height gauges and calipers today — your trusted partner for precision measurement in every industry.