In today’s era of advanced manufacturing, precision measuring instruments play a critical role in ensuring quality, consistency, and reliability. Whether you’re machining aerospace parts, producing automotive components, or conducting laboratory inspections, precision tools such as micrometers, calipers, dial indicators, and gauges form the foundation of every accurate measurement process.

What Are Precision Measuring Instruments?

Precision measuring instruments are high-accuracy tools used to determine dimensions, surface quality, or geometric tolerances. Unlike basic rulers or tape measures, these instruments offer micron-level accuracy and are essential in any industrial measurement environment where tolerances are tight and every micron matters.

Common examples include:

-

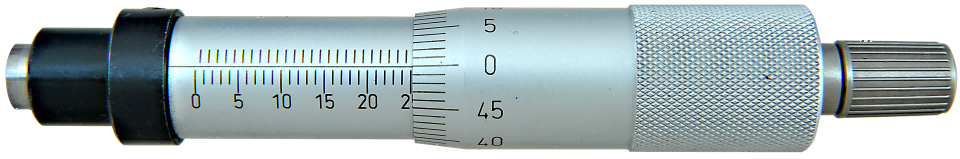

Micrometers – for measuring thickness, outside diameters, or internal dimensions.

-

Vernier Calipers – for multi-dimensional measurements in machining and assembly.

-

Dial Indicators – to detect small deviations in part alignment or runout.

-

Digital Gauges – providing quick, repeatable readings for production monitoring.

Why Precision Measurement Matters

In manufacturing, quality control isn’t just a checkbox — it’s the backbone of brand reputation. Even a deviation of 0.01 mm can lead to malfunctioning parts, production delays, or costly recalls. That’s why companies rely on ISO-certified measuring tools and consistent calibration procedures to maintain measurement integrity.

High-quality precision tools help:

-

Improve product accuracy and minimize defects.

-

Reduce material waste and production rework.

-

Maintain compliance with industrial standards such as ISO 9001 or ASME.

-

Increase productivity through faster, repeatable measurements.

Choosing the Right Measuring Tool

Selecting the right instrument depends on your specific application. For example, an outside micrometer is ideal for measuring shaft diameters, while a bore gauge or inside micrometer works best for internal measurements. When dealing with complex geometries, digital calipers or height gauges can offer greater flexibility and data output compatibility with modern manufacturing systems.

At Meapert, we provide a full range of precision measuring tools designed for demanding environments — from machinists’ workshops to quality-inspection labs. Each tool undergoes rigorous accuracy verification and calibration, ensuring reliable results every time.

Calibration and Maintenance: The Key to Longevity

Even the best measuring tools require regular calibration to maintain accuracy. Over time, wear, environmental factors, and handling can affect readings. Meapert recommends periodic instrument calibration, following traceable standards to ensure long-term consistency. Proper storage, cleaning, and handling can also extend the life of your tools and preserve their precision.

Conclusion

Precision measuring instruments are not just accessories — they are the silent guardians of product quality. As industries move toward smart manufacturing and tighter quality requirements, investing in reliable, well-calibrated measuring tools has never been more important.

Explore Meapert’s selection of micrometers, calipers, and industrial gauges today, and take your measurement accuracy to the next level.